Logiciel de restauration collective Octopus HACCP

La conformité HACCP en restauration collective

Un environnement complexe

La restauration collective se définit par la production et la distribution en grand nombre de plats cuisinés dans des crèches, cantines scolaires, restaurants d’entreprise, EHPAD, établissements hospitaliers, etc.

Elle s’adresse à une collectivité de consommateurs réguliers, à qui elle doit offrir une alimentation de qualité à prix modérés.

La restauration collective regroupe différents types de cuisines :

- Les cuisines centrales ou unités centrales de production, qui produisent des plats destinés à être livrés à des cuisines satellites ;

- Les cuisines satellites qui servent les plats aux consommateurs. Dans certains cas, elles peuvent aussi produire une partie du repas sur place.

Globalement, la restauration collective se caractérise par une organisation décentralisée, avec un lieu de production différent du lieu de distribution, ce qui implique une logistique rigoureuse en liaison froide et/ou chaude. Il arrive aussi que des cuisines sur place assurent la production de plats consommés exclusivement sur place.

Le périmètre de la méthode HACCP en restauration collective

La mise en œuvre de la méthode HACCP dans ces organisations est complexe, car le nombre d’intervenants, de produits à contrôler et de plats à produire est très important. La moindre anomalie dans les différentes procédures peut avoir des conséquences sanitaires graves.

La démarche HACCP concerne :

- La maîtrise de l’hygiène du personnel ;

- La maîtrise du nettoyage et de la désinfection ;

- Le choix de fournisseurs possédant un agrément sanitaire.

S’agissant de la gestion des denrées alimentaires, la réglementation HACCP repose sur :

- Un ensemble de contrôles à la réception des produits (type, numéro de lot, date limite de consommation, etc.) ;

- Le contrôle des températures de stockage en enceinte froide et chaude ;

- La maîtrise du couple temps/température dans les phases de préparation des plats ;

- La maîtrise des températures en liaison froide et chaude ;

- La maîtrise des DLC et DLC secondaire ;

- La maîtrise de la qualité microbiologique, etc.

Les contraintes en matière de contrôle et de traçabilité

La gestion HACCP d’une cuisine collective implique un nombre de contrôles et de relevés proportionnel au volume de denrées traitées. Chaque étape (réception, stockage, suivi des températures, production, livraison, suivi du nettoyage et de la désinfection, notification des anomalies et actions correctives) doit respecter un protocole strict et une traçabilité en amont, en interne et en aval.

Chaque opération donne lieu à un relevé qui doit être archivé avec des pièces connexes (étiquettes des produits, bons de livraison, déclarations d’anomalie, etc.). Il en ressort un volume considérable d’informations sur des supports divers qui doivent être stockés et conservés longtemps, et être accessibles en cas contrôle de routine ou suite à une alerte sanitaire.

Les avantages de la digitalisation HACCP dans la restauration collective

L’utilisation du logiciel de restauration collective Octopus HACCP garantit l’hygiène et la sécurité alimentaire en restauration collective, en conformité avec la réglementation HACCP.

Le logiciel de restauration collective, un outil simplificateur des procédures

La dispersion des lieux, le nombre d’intervenants, les quantités de denrées et le volume d’opérations et documents à enregistrer afin d’assurer le contrôle, la traçabilité et la production des pièces en cas d’audits et contrôles rendent laborieuse et risquée une gestion manuelle de la méthode HACCP en restauration collective.

C’est pourquoi l’utilisation d’une application HACCP est indispensable. Les fonctionnalités de cette application nomade pour tablette et mobile, compatible iOS et Android, ont été développées à partir des attendus de la réglementation HACCP.

Un accompagnement au quotidien des chefs, seconds de cuisine et agents

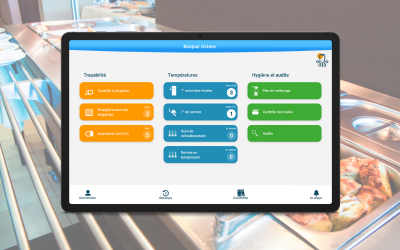

Le logiciel de restauration collective facilite la saisie des informations de contrôle lors des différentes phases et l’enregistrement des données de traçabilité directement depuis des écrans intuitifs :

- Traçabilité (amont, interne et aval), avec les rubriques Contrôle à réception, Enregistrement des étiquettes, Impression des DLC ;

- Températures, avec les rubriques Enceintes froides, Suivi de refroidissement (descente de température rapide) ;

- Hygiène et audits, avec la rubrique Plan de nettoyage.

Chaque rubrique du logiciel de restauration collective déroule ensuite un scénario conforme à la réglementation HACCP. Cela permet une saisie rapide et sécurisée des données (type d’aliments, température, DLC, DDM…), un suivi de la conformité des températures lors de la livraison des plats aux cuisines satellites et de n’oublier aucune des tâches prévues, notamment sur la partie Plan de nettoyage.

Numérisation de la gestion des étiquettes

L’enregistrement des étiquettes est fait dorénavant via l’appareil photo de la tablette où est installée l’application HACCP, tout comme l’archivage des bons de livraison et autres documents papier. Cette fonction intégrée associe directement les pièces avec l’opération en cours et la date du jour, pour un classement optimal et une recherche accélérée lorsque vous devez produire l’historique d’une journée.

L’édition des étiquettes de DLC secondaire se fait depuis le logiciel de restauration collective Octopus HACCP. L’application calcule automatiquement une nouvelle date limite de consommation lors du déconditionnement des produits et leur incorporation dans une préparation, et génère une étiquette à éditer et à apposer sur le bac du produit.

Des opérations de contrôle d’hygiène et de sécurité sanitaire facilitées

Les ingénieurs qualité et les responsables en charge de la sécurité sanitaire et des bonnes pratiques d’hygiène des cuisines centrales et des cuisines satellites peuvent contrôler à distance l’ensemble du dispositif et réagir rapidement en cas de non-conformité.

Lors des contrôles sanitaires, l’archivage numérique des données de traçabilité simplifie l’accès aux informations utiles. Il suffit de sélectionner une journée pour obtenir l’intégralité des données relatives aux produits et les documents associés (bons de livraison, étiquettes, numéro de lot, températures…).

Le module Document contient les données liées aux plans de maîtrise sanitaire (PMS) ainsi que les analyses bactériologiques effectuées en laboratoire.

FAQ

Qui est concerné par la mise en place d’un logiciel de restauration collective HACCP ?

La mise en œuvre d’un logiciel de restauration collective concerne toutes les équipes opérationnelles : ingénieur qualité, chef et second de cuisine, agent, responsable logistique liaison froide et/ou chaude.

Quels sont les avantages du logiciel de restauration collective HACCP ?

La digitalisation des procédures de vérification des denrées alimentaires et de la traçabilité amont, interne et aval simplifie le travail de saisie des informations (température, étiquettes, plan de nettoyage, etc.), sécurise les données, et permet de réagir rapidement en cas de non-conformité.

Comment le logiciel de restauration collective accélère la transition vers le zéro papier ?

Le logiciel de restauration collective Octopus HACCP intègre une fonction de sauvegarde associée à l’appareil photo de votre tablette ou mobile, qui permet de numériser tous les documents nécessaires à la conformité HACCP, comme les étiquettes (produit, numéro de lot, DLC), les bons de livraison, etc. Toutes ces données sont archivées par journée et type d’opération.

En quoi le logiciel de restauration collective est un atout lors d’audits et contrôles sanitaires ?

Toutes les données de traçabilité et les évènements sont numérisés et immédiatement disponibles pendant 5 ans. En cas de non-conformité, de contrôle sanitaire ou de simple audit, il est facile de ressortir l’historique d’une journée.